1.Colorful Corrugated Roofing Sheet Brief Introduction

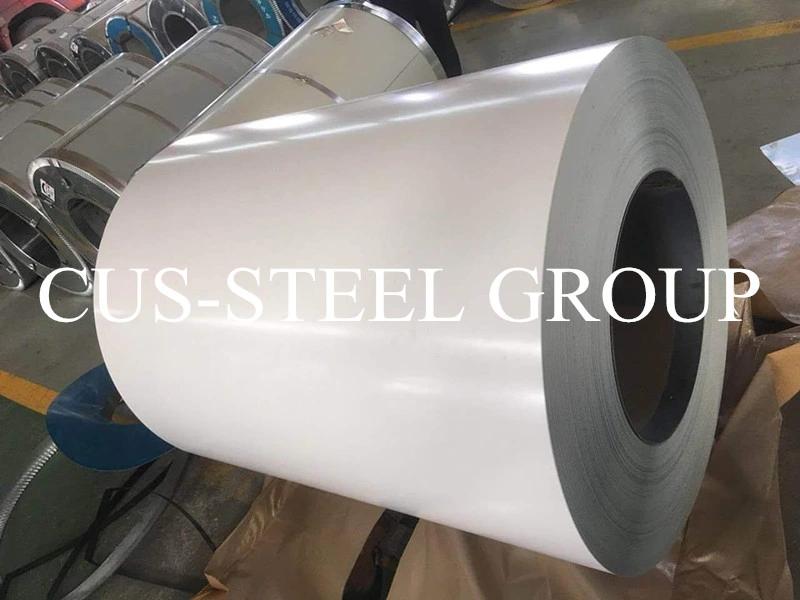

It is proceeding by the chemistry degrease and electroanalysis with the cold rolled steel coil and sheet, clean the oils

on the surface of steel, sufficiently heated to the proper temperature for zinc coating, pass by level up, strain rectify,

and then passivation or annoit etc.

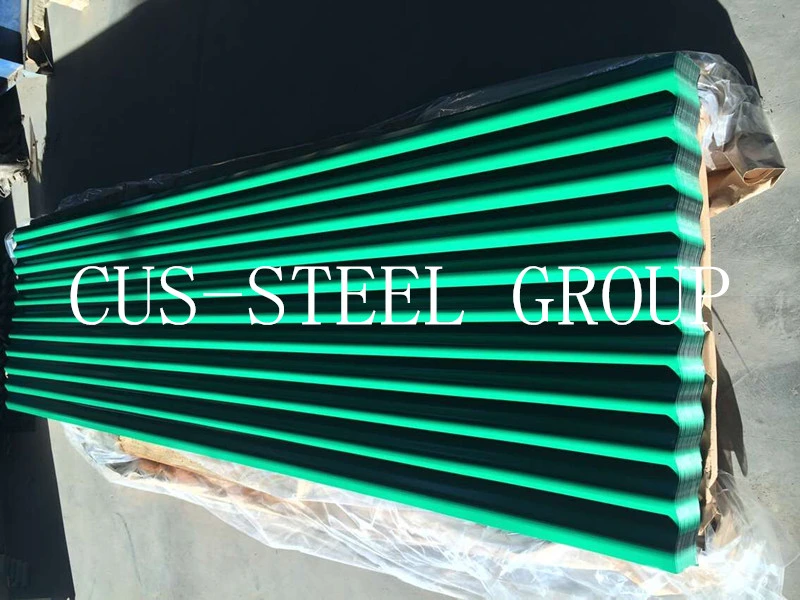

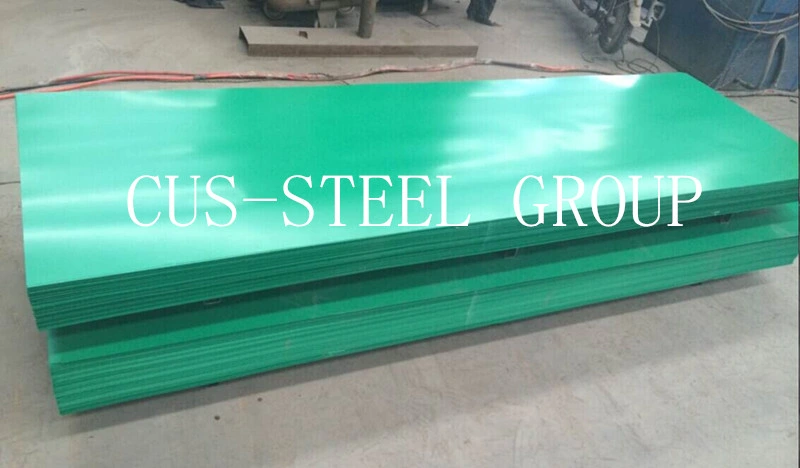

2. Colorful Corrugated Roofing Sheet Main Features

1) Protects against corrosion in air and water, and has allowed corrugated metal roofing to become one of the most

durable and withstanding roofing materials available

2) Has features of easy installation, high strength, low in costs, durable and nice appearance

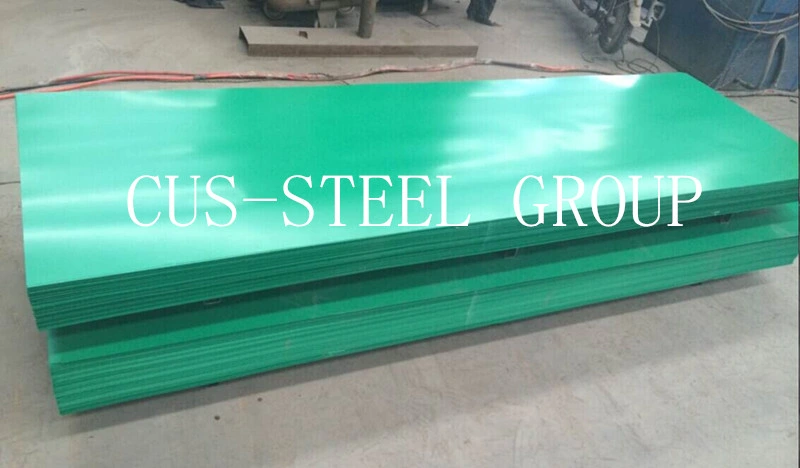

3. Colorful Corrugated Roofing Sheet Application

It is used as building materials(ceiling, metal roof tile) machinery parts (electrically controlled cabinets, road maintain

board, etc, so it is mainly used in advertising industry, construction, household appliances industry, electrical industry,

furniture industry and transportation.

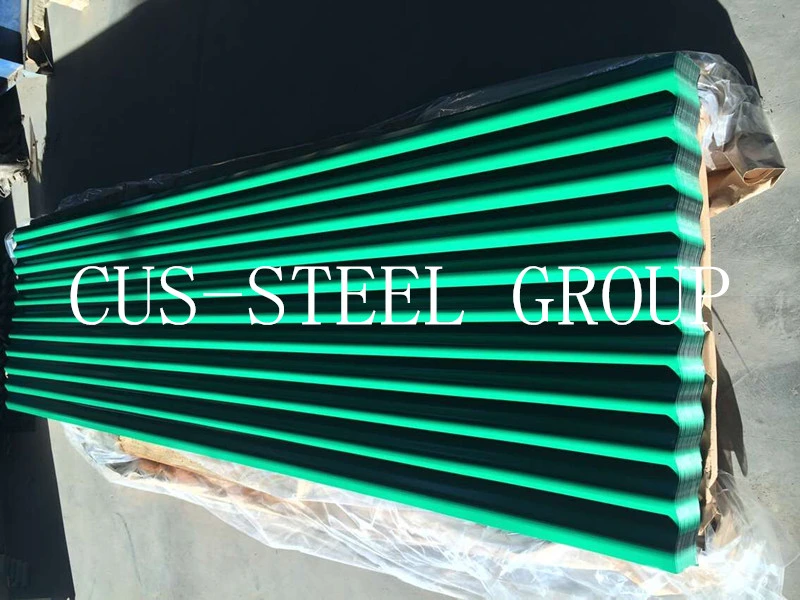

4. Colorful Corrugated Roofing Sheet Technical Processing

Hot rolled steel coil -->Cold rolled- >Hot dipped galvanized/ galvalume/painted- > Corrugated-->Packing

5. Colorful Corrugated Roofing Sheet Quality Control

Strict procurement process---skillful technical workers---final products inspection (resistance to corrosion,salt spray

test,exposure test,machinability,thermal resistance)---standard packing

Ral Color Card

The color can be made as per Ral color card or the samples.

Sara Tian

It is proceeding by the chemistry degrease and electroanalysis with the cold rolled steel coil and sheet, clean the oils

on the surface of steel, sufficiently heated to the proper temperature for zinc coating, pass by level up, strain rectify,

and then passivation or annoit etc.

2. Colorful Corrugated Roofing Sheet Main Features

1) Protects against corrosion in air and water, and has allowed corrugated metal roofing to become one of the most

durable and withstanding roofing materials available

2) Has features of easy installation, high strength, low in costs, durable and nice appearance

3. Colorful Corrugated Roofing Sheet Application

It is used as building materials(ceiling, metal roof tile) machinery parts (electrically controlled cabinets, road maintain

board, etc, so it is mainly used in advertising industry, construction, household appliances industry, electrical industry,

furniture industry and transportation.

4. Colorful Corrugated Roofing Sheet Technical Processing

Hot rolled steel coil -->Cold rolled- >Hot dipped galvanized/ galvalume/painted- > Corrugated-->Packing

5. Colorful Corrugated Roofing Sheet Quality Control

Strict procurement process---skillful technical workers---final products inspection (resistance to corrosion,salt spray

test,exposure test,machinability,thermal resistance)---standard packing

| Steel Grade | DX51D,SGCC,SPCC,S350,G550.etc |

| Thickness | 0.12mm--1.2mm |

| Effective Width (after corrugation) | 665mm, 750mm, 815mm, 840mm, 900mm ,925mm,1020mm, 1025mm, 1050mm ,etc |

| Base metal | Galvanized/galvalume/ Aluzinc /prepainted (PPGI,PPGL) Steel sheet |

| Zinc coating | Z30-275gsm,AZ30-180gsm |

| Coating type | PE,SMP,PVDP, HDP |

| Painting Type | 2/2 2/1 |

| Lenght | Generally 1830, 2440, 3000, 3660mm, any length can be customized according to the transportation,generally less than 11.8m |

| Delivery | Within 15~20 working days after receiving deposit |

| Packing | Export standard seaworthy packing. Waterproof paper+steel sheet+bundle with steel strips(3-4pcs) |

| Price | FOB&CNF&CIF price |

| Payment terms | TT or L/C |

Ral Color Card

The color can be made as per Ral color card or the samples.

Sara Tian