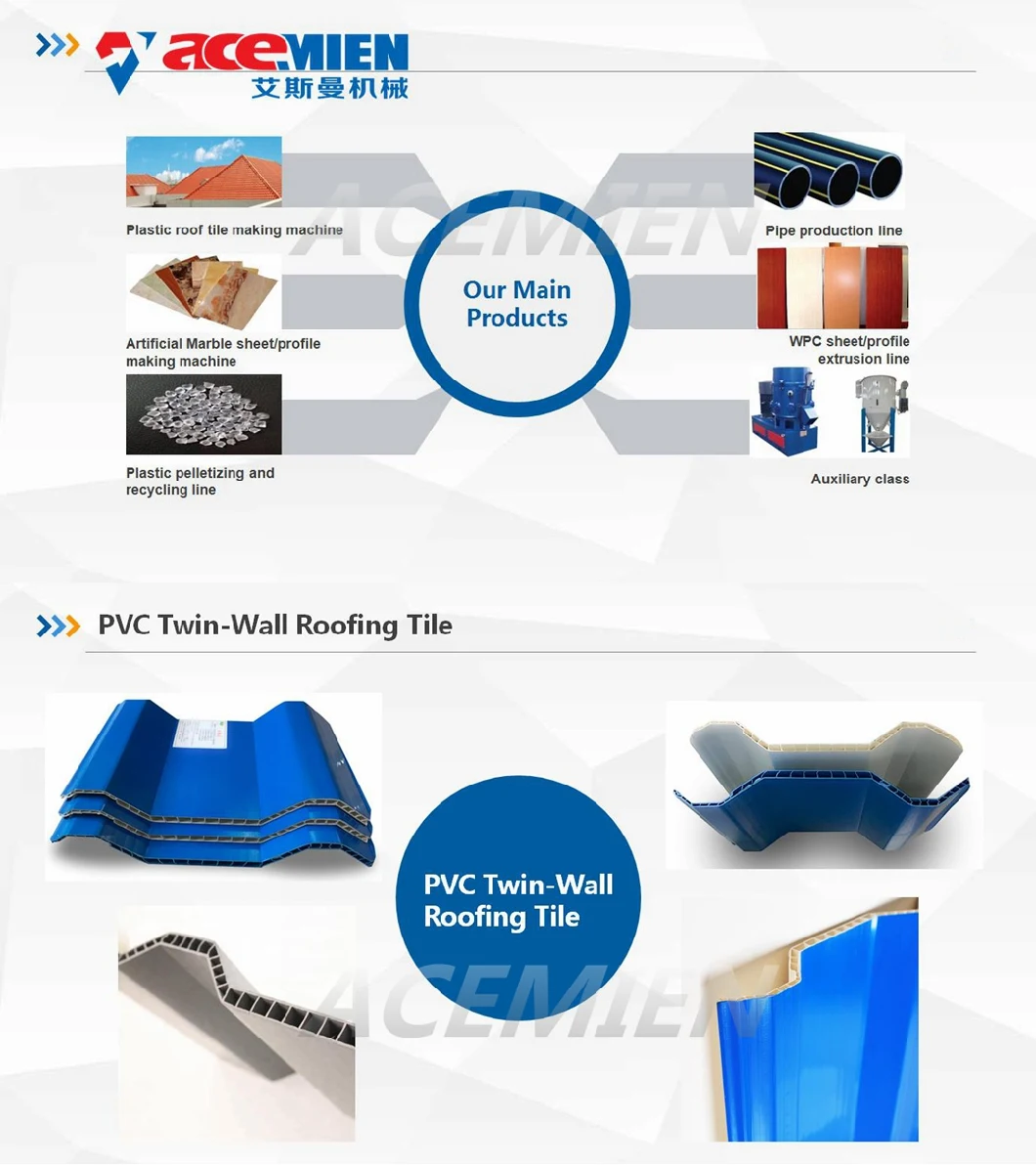

Product Description

PVC Twin - wall Hollow Roofing sheet extrusion machine

Advantage:

1)This twin-wall hollow roofing sheet is better for heat and sound resistency.

2)It is suitable for tropical weather, with advantages of anti-corrosion, rustproof, strong durability.

3)Beautiful appearance, easy and fast installation.

Application:

Twin-wall hollow roofing sheet is widely used in the factories(including chemical and treatment plants),sports stadium, school, agricultural industry, marine. products, warehouse, commercial building.

Machine list

| No. | Machine | Qty. |

| 1 | Screw loader for SJZ 80/156 extruder | 1set |

| 2 | SJZ 80/156 conical twin-screw extruder(PVC) | 1set |

| 3 | Vacuum loader and drying hopper | 1set |

| 4 | SJ50/30 single screw extruder(ASA) | 1set |

| 5 | Extrusion mould and distributor | 1set |

| 6 | Forming table | 1set |

| 7 | Haul off unit | 1set |

| 8 | Cutter | 1set |

| 9 | Stacker | 1set |

| 10 | Screw loader for Mixer | 2sets |

| 11 | SRL-Z300/600 Mixer unit | 2set |

| 12 | Crusher | 1set |

| 13 | Pulverizer | 1set |

Project evaluation

Raw material & Final product:

| Raw material & formulation | PVC powder, CaCO3, CPE, PE-WAX, Stearic acid , Compound stabilizer ,ACR, paraffin,ASA granule |

| Description final product | Two-layers Hollow Corrugated PVC Roof Tile Width:760-1340mm or custormized Thickness: 1.5-4mm normally |

| Output capacity | Output:350-400kg/h(Depending on CaCO3 proportion) |

Work condition (provide by customer)

| Warehouse/Workshop | Dimension (M*M*M): 25(Length)×5(width) ×3.5 (Height) Crane: Machine positioning |

| Temperature & Humidity | ≤40ºC, ≤95% |

| Power supply | 3-phase, 380 V, 50 Hz(or customized) |

| Wire/cables: | Wires/cables from power supply to control cabinet of this production line; |

| Cooling Water hose/pipe | Water supply to machines and pools |

| Lubrication oil: | Sinopec, Exxon mobile |

| Compressor | 7.5kw(0.6-0.8Mpa) |

Energy consumption

| Installation power | Suggested 250KVA transformer |

| Cooling Water | ≤20ºC, ≥0.3Mpa, ~5-6tons/hr |

| Compressed air | 0.3m3/min, >0.6Mpa |

| Manpower | 3 Persons/shift (24 hours need 2 shifts) |

About Jiangsu ACEMIEN Machinery:

Jiangsu ACEMIEN Machinery Co., Ltd is specialized on plastic extrusion and recycling machinery manufacturing.

We have been producing and selling for over 5 years. Our equipment is exported to Asia, Africa, etc,

We have top-ranking Research and Development technology system and rich experienced technician team.

Our vision is to offer you the best and the most appropriate plastic extrusion and recycling solution, to offer you the most reliable technically and commercial service support.

Turnkey project service:

1. we will provide all the machines for the complete production according to customer's requirements.

2. we will provide complete service for factory layout and other information to help customer to build the factory.

3. we can also provide the raw material to the customer if you need.

4. we will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer. we are the professional and trustable supplier for turnkey projects. Let us do win-win business together.