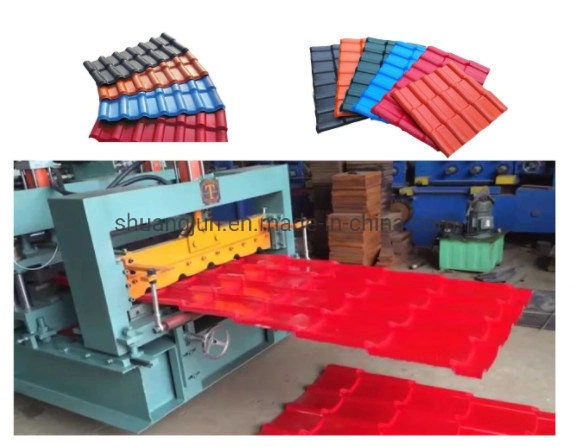

PVC Resin Glazed Corrugated Roofing Tile Production Line Plastic Co-extrusion

Introduction:

Plastic glazed tiles are new type of plastic glazed tiles, also called synthetic glazed tiles or PVC glazed resin tiles. The product is processed by two layers if co-extrusion technology. Each layer of material has its own functional surface material: it's a super weather-resistant resin to ensure the durability and chemical resistance of the products, mainly used in flat roofs, villas, a house, garden pavilions and other roof areas. and this product is a new generation of permanent roofing material designed with advanced foreign technology and designed for corrosive plants and heavy acid rain areas.

Machine group:

Product features:

1. energy saving

2. impact resistance, good low temperature resistance

3. lasting color

4. excellent anti-loading

5. excellent self-water resistance

6. light weight and self-cleaning

7. excellent corrosion resistance

8. fire resistance reach B1 level

9. volume is stable

10. insulation

11. simple installation

Introduction:

Plastic glazed tiles are new type of plastic glazed tiles, also called synthetic glazed tiles or PVC glazed resin tiles. The product is processed by two layers if co-extrusion technology. Each layer of material has its own functional surface material: it's a super weather-resistant resin to ensure the durability and chemical resistance of the products, mainly used in flat roofs, villas, a house, garden pavilions and other roof areas. and this product is a new generation of permanent roofing material designed with advanced foreign technology and designed for corrosive plants and heavy acid rain areas.

Machine group:

| 1 | 80 conical twin screw extruder & 50 single screw extruder | SJZ-80B SJ-50*30 | 1 set 1 set |

| 2 | hanger mould | YJM1100 | 1 set |

| 3 | distributor | type A/AB/ABA | 1 set |

| 4 | hopper dryer | STG-160 | 1 set |

| 5 | two-roll printing group | YH1100 | 1 set |

| 6 | water temperature controller | 1 set | |

| 7 | glazed tile forming machine | SJW 250*880 | 1 set |

| 8 | saw blade cutting | SJW 1100 | 1 set |

| 9 | receiving rack | SJW 1100 | 1 set |

Product features:

1. energy saving

2. impact resistance, good low temperature resistance

3. lasting color

4. excellent anti-loading

5. excellent self-water resistance

6. light weight and self-cleaning

7. excellent corrosion resistance

8. fire resistance reach B1 level

9. volume is stable

10. insulation

11. simple installation

Company Introduction

Shanghai shuangjun machinery is located in Shanghai city, China, a beautiful and famous city in the word.

We have 20000 square meters land and new modern workshop, we mainly development, design, manufacture and marketing plastic pelletizing machine, plastic recycling machine, pet bottle recycling machine, PVC pipe making machine, PE pipe making machine, PVC foam board production line, plastic granulator, plastic shredder, plastic pulverizer, Plastic agglomerator, single shaft shredder, double shaft shredder, plastic crusher and so on. By the several years developing, we grown up to a middle scale company in China plastic industry.

As one of the reliable supplier in China, We have keeping improved our management and technology level. Up to now, we have earned good reputation in domestic and abroad market. And our products have been exported to many countries, like Mexico, America, Argentina, Chile, Brazil, Russia and so on.

Quality and honest is our foundation, customer satisfactory is our job, to get "Win-Win" is our main target. We always focus on improving our quality. And we have built up a professional after-sale services team with rich-experienced in machine commissioning and installation. We believe our quality and service will bring success to each customer.

Welcome final users and distributors from all the world contact with us and create success.

With your support and our effort, we deeply believe that the tomorrow of shuangjun will be much better.

FAQ

Q: What is your terms of payment?

A: 100% T/T in advance,or 50% T/T in advance,50% balance before shipment.

Q: What is your terms of packing?

A: Generally, we pack our goods in plywood box for big machine.

Q: Can you produce according to the samples testing?

A: Yes, we can make testing by your sample or technical drawing.

Q: Warranty and after sales service?

A: We provide 1 year warranty free for spare parts,Whole life technical support.