Gel coat fiberglass Roofing Sheet FRP Skylight Sheet Forming Machine

Machine function

This machine can produce lighting sheet,color sheet,common flat sheet and gel coat sheet.

This machine is more intelligenter than the standard one,more fater production speed,more easy for operating.

Resin Resin and fiberglass get infiltration

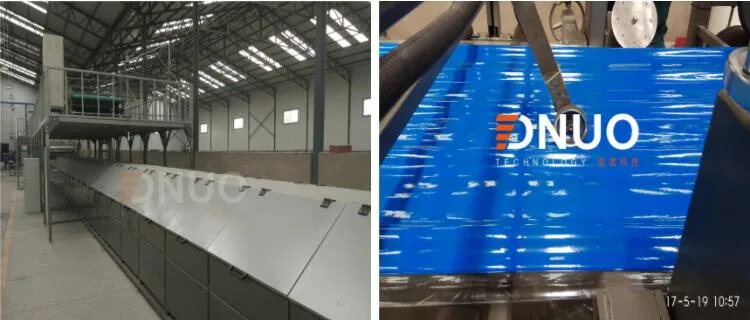

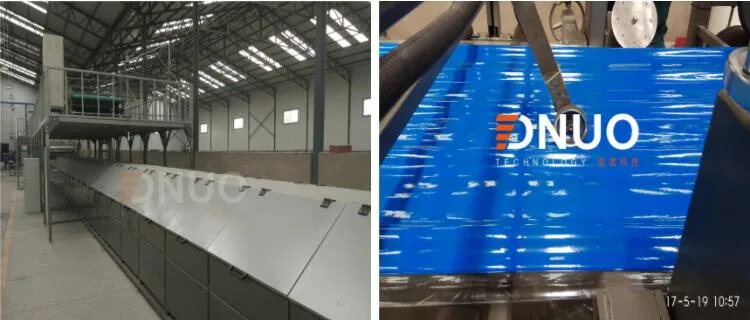

Three sets of towel shape heating oven FRP sheet

our machine equipts with electric saw cutter also,if the thickness of sheet is more than 2mm,we use the electric saw to cut the useless edge.

This machine is more intelligenter than the standard one,more fater production speed,more easy for operating.

Basic parameter | |

Operation Staff | 3-6 person |

Production speed | 2-12m/min |

Sheet width | Maximum effective width of flat sheet is 1500mm |

Wave height | maximun 145mm |

Sheet thickness | 0.4-5mm |

Power requirement | 120kw |

Machine size | 61m(L)×4m(W)×5(m) |

Power consumption | 55kw/h |

Machine characteristics

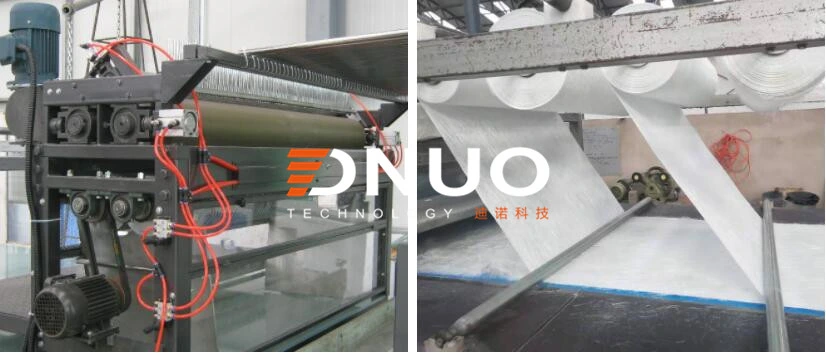

1.Apply high precision import forging doctor blade, smaller error, Thin & even gel coat coating.

2.Gel coat curing area apply clip flatten roller designed by Dnuo technology company, easy operation & good tensioning effect.

3.The impregnation table can control temperature independently & accurately. It can adapt to the outside temperature fast, impregnation fast and improve the production speed effectively.

4.Pulse free metering system, accurate metering, and wide flow rate adjustment range. It can add powder filler.

5.Easy operation based on PLC intellectual control system. Operate by two computers, the production task and equipment operating data is faster and intuitional. Only short-term training can make operators complete production independently.

6.Three separate ovens for temperature control, Unique temperature control arithmetic makes oven heating fast, temperature control precise. Which improve quality of products, reduce energy consumption and shorten the preparing time effectively. This way makes sheets curing better.

7.Metering control system and Roving chopper speed can be synchronous with the production line.

8.Special cross cutting machine and good synchronization performance make cutting accurately.

9.All the machine parts adopt international standard steel make machine with high stability.

10.System failure can be automatically alarmed and show fault point. Make maintenance easily.

11.Particular parts adopt special purpose wire, durable in use.

12.Size and layout of machine can be made according to customer requirements

Detailed images

Resin Resin and fiberglass get infiltration

Three sets of towel shape heating oven FRP sheet

| Roving chopper | Chopped strand mat |

| The roving chopper can cut fiberglass into 38mm fiberglass and throw them on resin uniformly. | Our machine also equipment with chopped stand mat frame,you can use fiberglass roving roving and mat as your request. |

| Infiltration platform | Thickness controller |

| PID temperature control,multi-line independent temperature control can make the resin and fiberglass get infiltration more faster and better,improve the speed of production | hard and soft sheet thickness rollers,can achieve precise control thickness of the sheet and eliminate the bubbles |

| Heating oven | Cross cutting system |

| 1.The PID control system can accurately control the temperature 2.Circulation heating,ovens are often alternate work can reduce energy 3.Can put two set of molds on the reversible mold holder, that can realize continuous production. | Special cross cutting machine can synchronize move with sheet. Many factories can'r realise synchronous cutting,because their cutting machine is static can't move with the sheet.so meet the problem of tracking |

Dust-free cutting device cut the useless edge

It is with no noise,no dust,can save energy.If the thickness of sheet is under 2mm,we use this device.our machine equipts with electric saw cutter also,if the thickness of sheet is more than 2mm,we use the electric saw to cut the useless edge.

Our Company

Qinhuangdao Dinuo Technology Development Co. Ltd.

1. 20-YEAR FRP Sheet making machines manufacturer in China.Independent research

and development design.We are the first domestic production of FRP sheet making

machine and biggest-selling company.

2. We have two production lines in our factory, Intelligents FRP gel coat sheet production

line and 3.2m wide FRP flat gel coat sheet production line.The visiting customers can see

whole running state of our machine.

3. Have obtained ISO 9001 Certificate and CE certificate.

4.Our machine have been exported to more than 40 countries,such as Maxico,Russia,Chile,Brazil,Thailand,Bangladesh,India,Indonesia and Columbia,our engineershave rich experience to install,debugging and trainning the workers.

Our factory

We have two production lines in our factory,you can see the whole production process on your visiting.

Intelligent Gel coat sheet machine 3.2m wide FRP gel coat flat sheet machine

After sales service:

1. Guarantee for 1 year excluding wire and electrical parts. Extra fee is paid if out of date.

Any damage to the machine caused by improper use will be charged.

2. The equipment is fully test before delivery.

3. Free installation, training and commissioning on site to help the operators operate

as soon as possible.

4. We will provide wear and electrical parts when you need.

Engineer install the machine over seas

Packing & Delivery

FAQ

1.Are you manufacturer or trader

we are leading manufacturer for FRP sheet making machine,we can also supply FRP sheet and raw materials for

FRP sheet.

2. Can I order the product with special size

Of course , your special requests and needs is acceptable here . the most advantage of us is providing

comprehensive planning and engineering

3. Why we are your best choice

We have our factory and many years of export and oversea installation experience, and free training ,

timely delivery, also providing good after-sales service, therefore we win good reputation among our customers

we are leading manufacturer for FRP sheet making machine,we can also supply FRP sheet and raw materials for

FRP sheet.

2. Can I order the product with special size

Of course , your special requests and needs is acceptable here . the most advantage of us is providing

comprehensive planning and engineering

3. Why we are your best choice

We have our factory and many years of export and oversea installation experience, and free training ,

timely delivery, also providing good after-sales service, therefore we win good reputation among our customers